Equipment & Capabilities

Discover the driving force behind precision manufacturing at Ultra Manufacturing. Our state-of-the-art equipment lineup is engineered to elevate your production efficiency and quality. From metals like Alloys, Aluminum, Brass, Exotics, Stainless Steel, Plastic, to Titanium, our machinery is finely tuned to meet diverse needs. Explore the tools that power innovation and excellence in every project, showcasing our commitment to advancing manufacturing standards.

Equipment

Swiss Lathes

Tsugami B0326II

Star SR J11 Type A Lathes

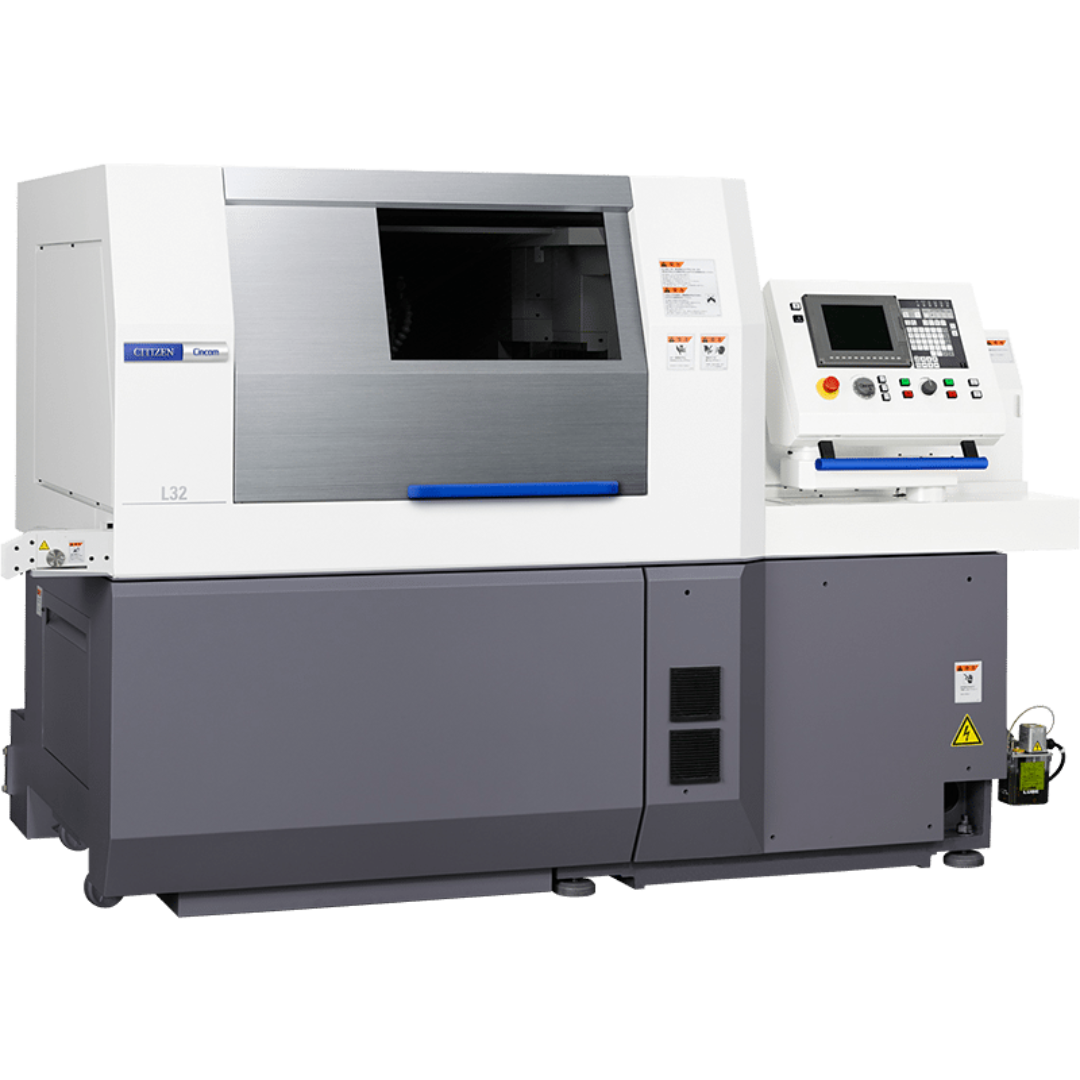

Citizen Cincom L32 (1)

Mills

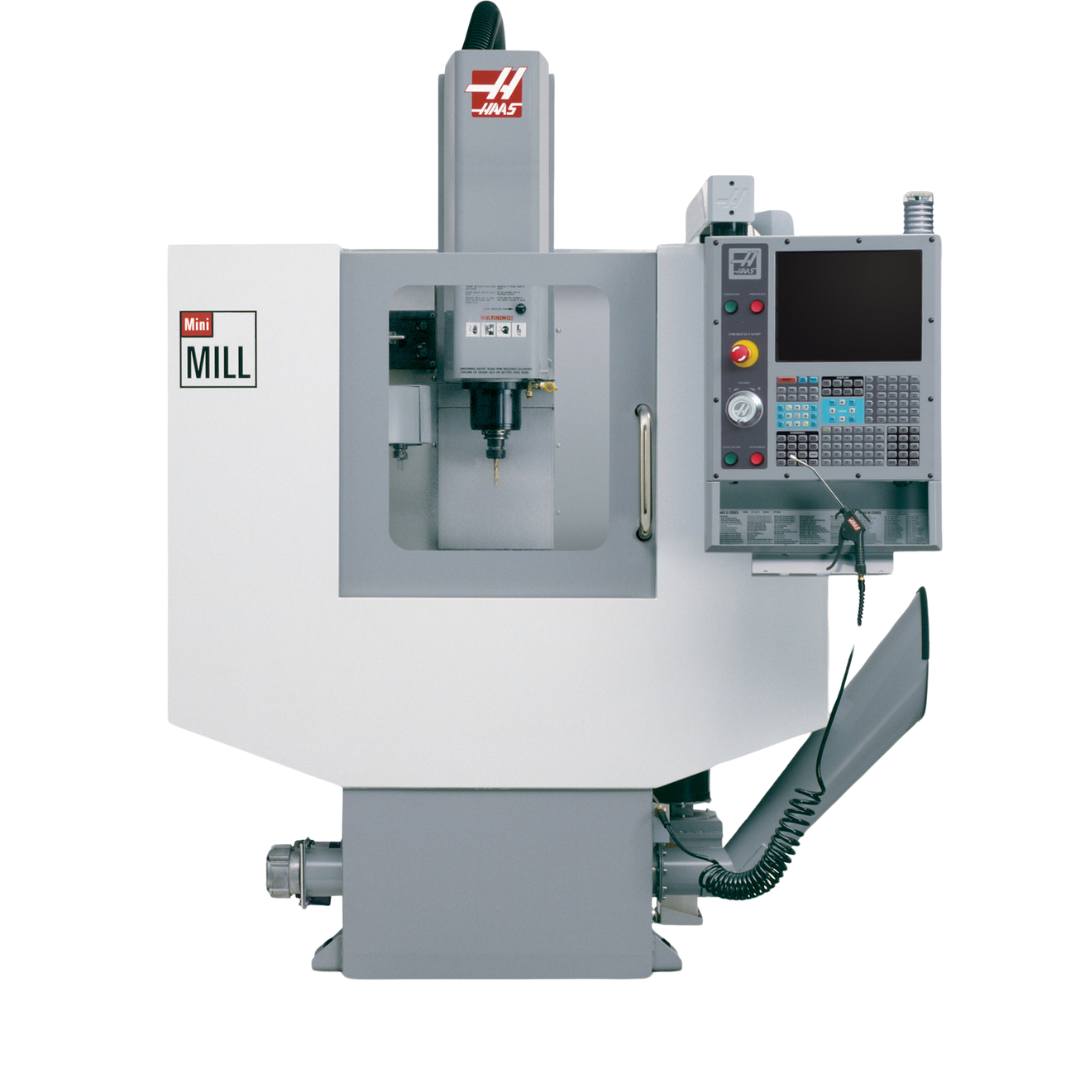

HAAS Mini Mill (1)

HAAS VF-4SS Vertical Mills

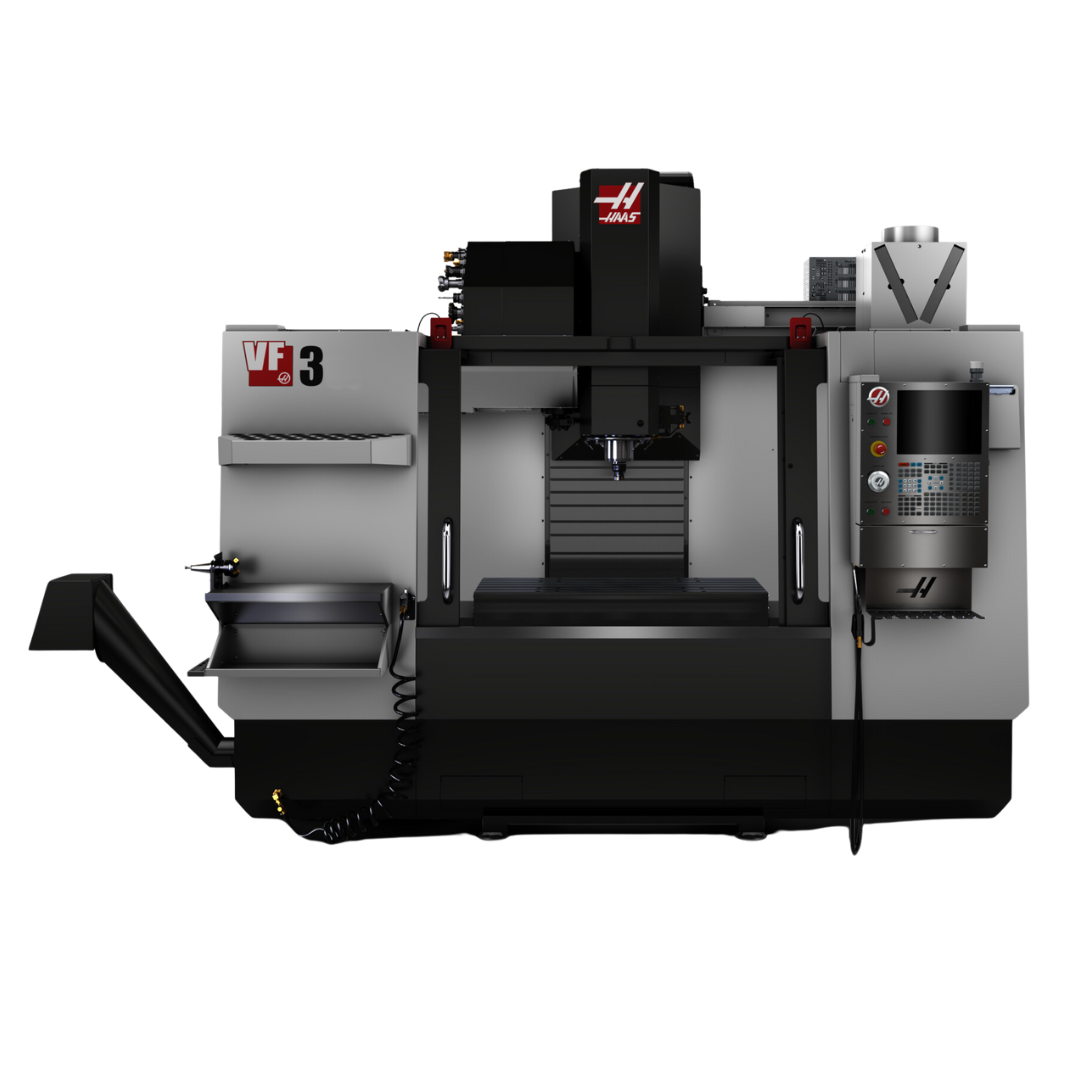

HAAS VF3 Vertical Mills

Lathes

Mazak Horizontal Quick Turn Smart 100S

Hyundai Kia SKT-21 Lathes

HAAS - CNC Lathes ST-20 and Sl-20

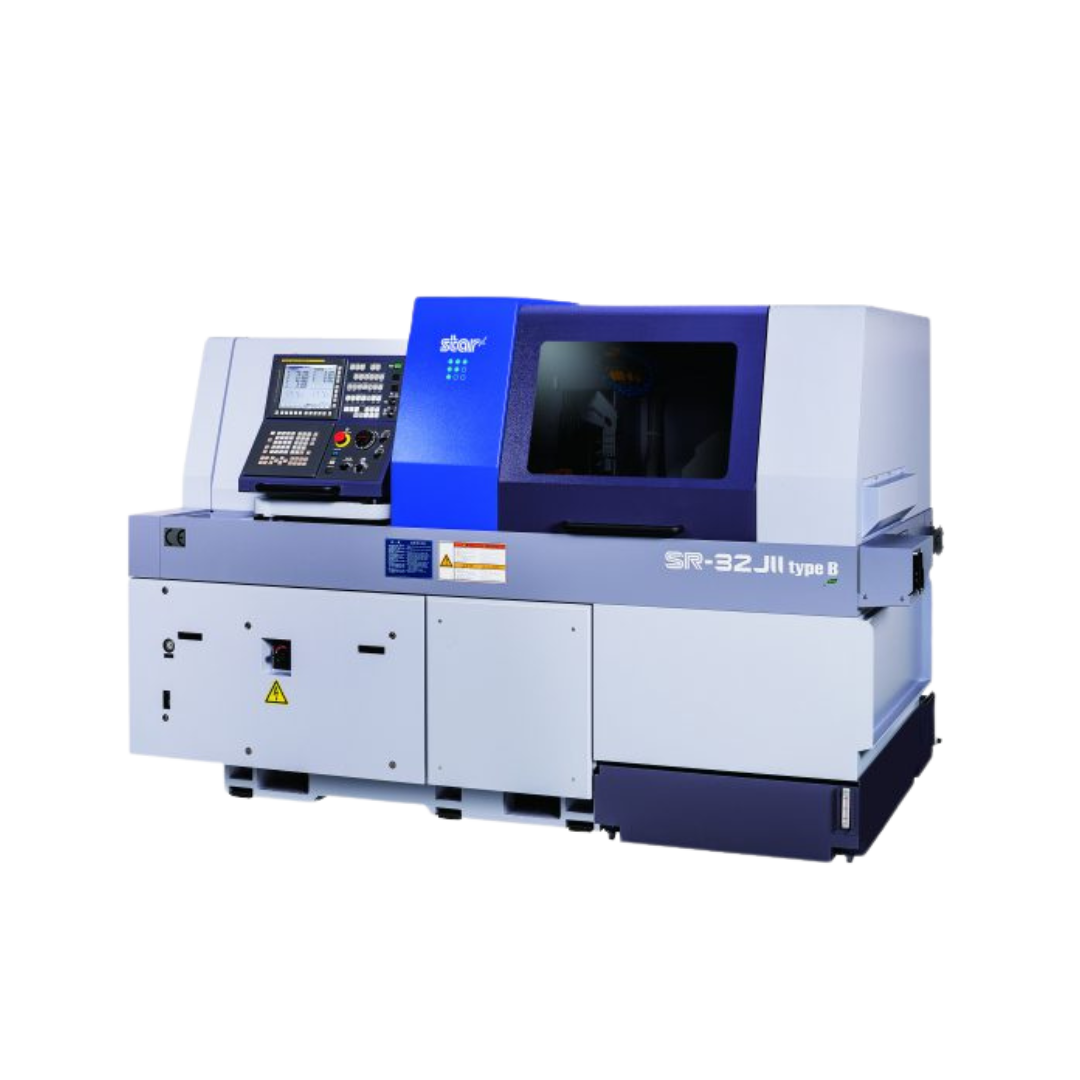

SR-32 JII Type A/B CNC Swiss-type Automatic Lathe

Mazak Quick Turn 250MSY CNC Turning Center

Hardinge Conquest Super Precision Lathes

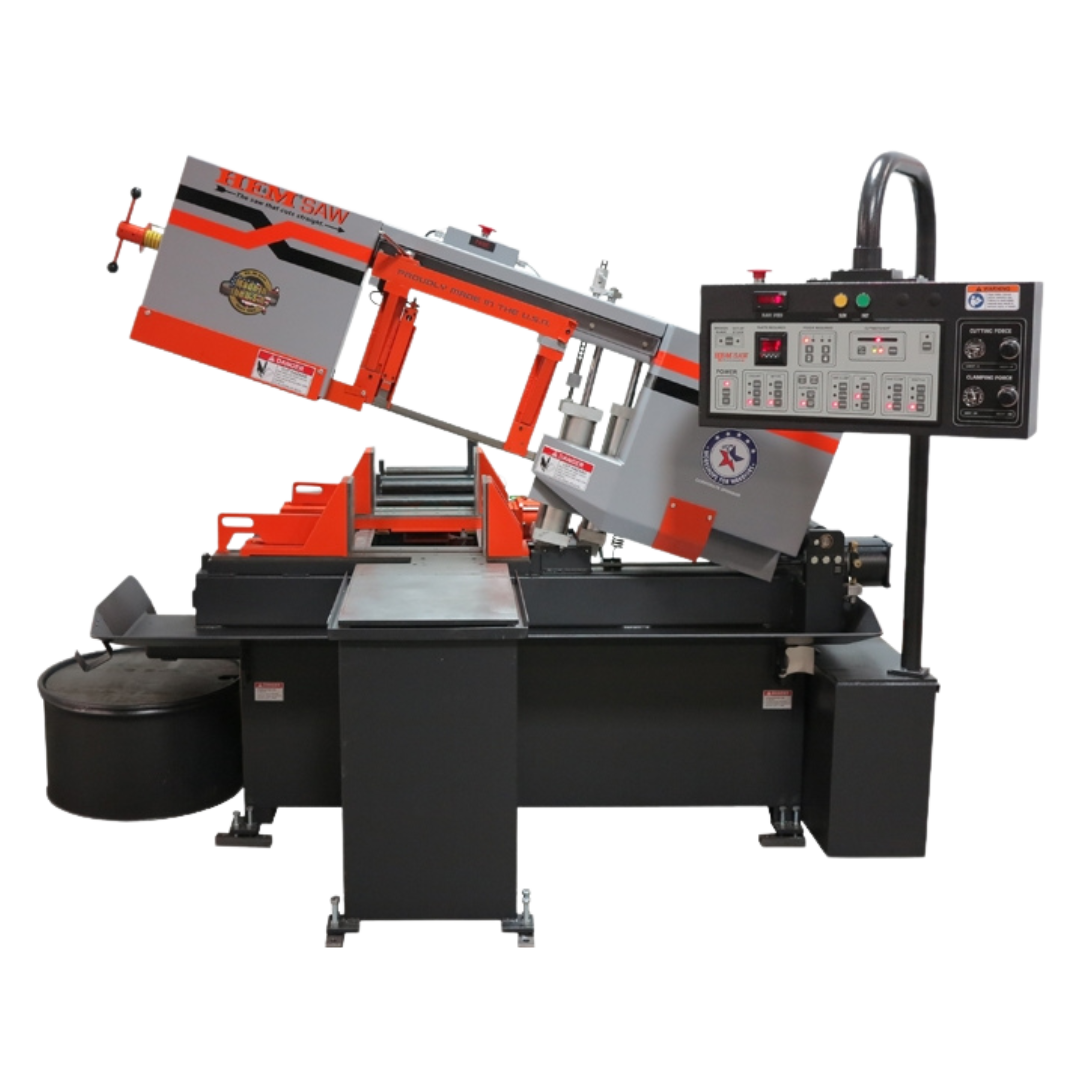

Saws

HemSaw H90A-4

.

Kalamazoo Automatic Horizontal Cutoff

Our Capabilities

CNC Milling

Our machining centers are equipped with the most advanced technology, enabling us to machine the precision parts on-time and on-budget. Our capabilities consist of:

- 3 and 4 axis milling capabilities for an array of possible part shapes.

- Machines are maintained to provide durability and dependability for accuracy and consistency.

- Larger Vertical Mills equipped with Midaco Pallet changers that increase uptime and reduce cycle times.

- Many late model machines with latest technology.

- All CNC equipped and programmed controlled to increase productivity.

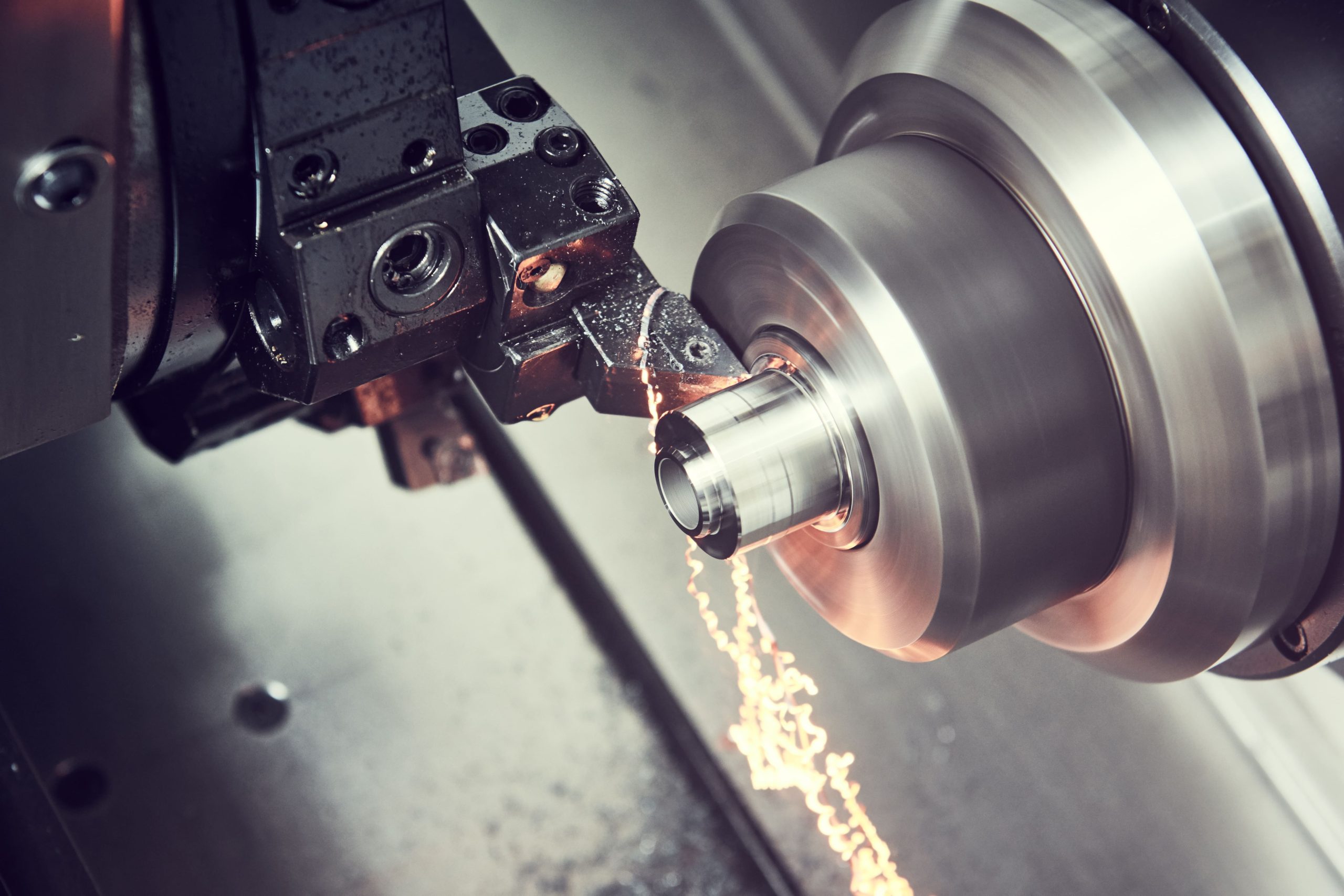

CNC Turning

Precision parts from Ultra with our CNC lathes , produce fast, accurate, and aggressive metal removal capabilities we are your single source provider of turned part.

- Bar feeding machines, allowing unattended operation.

- 2 spindle machines plus Y axis allowing off center milling.

- Tool spindles allow the precision turning, drilling, milling and tapping of parts.

- Machines are maintained to provide durability and dependable for accuracy and consistency.

CNC Turning

Precision parts from Ultra with our CNC lathes , produce fast, accurate, and aggressive metal removal capabilities we are your single source provider of turned part.

- Bar feeding machines, allowing unattended operation.

- 2 spindle machines plus Y axis allowing off center milling.

- Tool spindles allow the precision turning, drilling, milling and tapping of parts.

- Machines are maintained to provide durability and dependable for accuracy and consistency.

Swiss Turning

Complexity in parts can be produced on our late model Swiss lathe turning machines. Machines can process very small parts very accurately.

- Many tooling variations can be applied for complex parts.

- Very rigid stability in the bar to eliminate any vibration, chatter and allow high quality finishes.

- Machines run almost unattended with bar feeders to continue operation.

CNC Milling

Our machining centers are equipped with the most advanced technology, enabling us to machine the precision parts on-time and on-budget. Our capabilities consist of:

- 3 and 4 axis milling capabilities for an array of possible part shapes.

- Machines are maintained to provide durability and dependability for accuracy and consistency.

- Larger Vertical Mills equipped with Midaco Pallet changers that increase uptime and reduce cycle times.

- Many late model machines with latest technology.

- All CNC equipped and programmed controlled to increase productivity.

CNC Turning

Precision parts from Ultra with our CNC lathes , produce fast, accurate, and aggressive metal removal capabilities we are your single source provider of turned part.

- Bar feeding machines, allowing unattended operation.

- 2 spindle machines plus Y axis allowing off center milling.

- Tool spindles allow the precision turning, drilling, milling and tapping of parts.

- Machines are maintained to provide durability and dependable for accuracy and consistency.

Swiss Turning

Complexity in parts can be produced on our late model Swiss lathe turning machines. Machines can process very small parts very accurately.

- Many tooling variations can be applied for complex parts.

- Very rigid stability in the bar to eliminate any vibration, chatter and allow high quality finishes.

- Machines run almost unattended with bar feeders to continue operation.